ComBi D1000® is a combination gauge for coatings on iron, steel and non-ferrous metals.

ComBi D1000® functions and features:

• Automatic detection of the substrate and adjustment of the required measuring method

• Immediately ready for measuring without any intricate calibration

• High measuring range from 0 to 1.25 mm

• High measuring precision

• Also suitable for continuous measurements

• The V-groove on the measuring head makes measuring easier on round parts

• User-friendly

• Comfortable one-hand operation through cordless construction with integrated measuring sensor

• Display switchable from microns to millimeters

• Easy-to-read LCD display

SaluTron® D1: Combination gauge with interchangeable probes SaluTron® D1: Combination gauge with interchangeable probes

• Waterproof under IP Code 65

• Easy operation and setup by leading menu

• Quick zeroing and calibration of the gauge

• Display of measurement results in µm or mm

• High accuracy

• Continuous measurement possible

• V-groove enables measurements on axles or staves

• Automatic probe detection

• Setup of language: English or German

• Automatic switch off

• Battery capacity indication

• Display backlight

|

|

SaluTron® D2X:

All the functions of SaluTron® D1 with added measurement memory and a number of other features:

• 8,192 memory slots

• Large, easy-to-read display with backlight

• Measured values can be stored in blocks

• Calculation of average, standard deviation, minimum, maximum and coefficient of variation in single and multiple blocks

• Input of data, such as date and time of the measuring blocks, for reports

• RS 232 serial or USB port for interfacing to PC

• Output of measuring report to serial-, IR-printer or PC

• Output of measured values in different standard formats such as Excel, Lotus, etc.

• Setup of parameters for data transfer (baud rate, parity, data length)

• Acoustic signal upon exceedance of tolerance limits

• 16 application memories for special calibration

|

|

SaluTron® D4:

Measures all non-magnetic coatings such as synthetics, lacquers, enamels, copper, chromium, zinc, etc. on steel or iron (Fe sensor).

SaluTron® D5:

Measures all isolating coatings such as lacquers, synthetics, enamels, paper, glass, rubber, etc. on copper, aluminum or brass. This also includes eloxal coatings on aluminum (NFe sensor).

|

|

| |

|

SaluTron® D4 / D5 functions and features:

• Easy to use

• Measuring range 0–5 mm

• High accuracy

• 2 measurement modes: single-point or continuous

• Vibrations do not influence the measurements

• Wear resistant, spring-loaded ruby probe

• Display of measurement results in µm or mm

• Gauges can be switched on/off manually or automatically

• Visual alarm if the gauge is placed on incorrect substrate or if coating thickness exceeds the maximum range

• Integrated probe for single-handed use

• Easy setup

• Requires no time-consuming re-calibration for different materials

• V-groove for easy placement of the probe on round surfaces (rods, pipes, etc.)

|

|

SaluTron® D4 plus / D5 plus functions and features:

• Infrared transmitter

• USB interface

• 8,192 memory slots, dividable in max. 99 blocks and statistical data entries

|

|

|

SaluTron® D6 is a combination gauge with interchangeable probes (3 Fe and 2 NFe probes). The Fe-probes (F400, F1 and F10) allow the measurement of non-magnetic coatings such as paints, plastics, chromium, copper, zinc, enamel, etc. on steel and iron substrates. The NFe-probes (N1 and CN02) allow the measurement of non-conductive layers such as paints, enamels, plastics, rubber, glass, paper, etc. on non-magnetic metal substrates, such as aluminum, copper, brass, zinc and certain grades of stainless steel. Also suitable for the measurement of anodized aluminum.

Measuring features:

• Measuring range: 0–1250 µm (F1 standard probe)

• Measuring range: 0–10 mm (F10 special probe)

• High accuracy

• Switch between microns and millimeters

• Preset of minimum and maximum limits with visual and audible alarms upon exceedance

• 2 measurement modes: single-point or continuous

• 2 operation modes: direct mode with 99 memory slots and batch mode with 495 slots (5 blocks with 99 values each)

• Automatic probe detection

• Quick calibration and zeroing

• 2 calibration methods: correction of probe error system with basic calibration method

Functions:

• Statistic values: mean, minimum, maximum, number of measurements and standard deviation

• Switch between manual or automatic memory

• Delete function: single piece of data or all data in memory

• Analysis of measured values via histogram

• Acoustic signal after each measurement / adjustable button sounds

• Backlight

• Battery capacity indication

• Automatic or manual shutdown

• Transfer of results to PC

|

|

ComBi D3® is a coating thickness gauge for magnetic and non-magnetic substrates.

Combi D3® functions and features:

• Easy to use

• Large measuring range: 0–3.5 mm

• High accuracy

• 2 measurement modes: single-point or continuous

• Vibrations do not influence the measurements

• Wear-resistant, spring-loaded ruby probe

• Switch between microns and millimeters

• Automatic or manual shutdown

• Visual alarm if the coating thickness exceeds the maximum range

• Integrated probe for single-handed use

• Easy set-up by following the menu

• Requires no time-consuming re-calibration for different materials

• The V-groove on the measuring head makes measuring easier on round parts

|

|

|

ComBi D3® plus

The ComBi D3® plus is even more practical. A large memory, infrared sender, USB interface and software with statistic functions enable saving and editing the measurement results.

Additional accessories for ComBi D3® plus:

• Infrared sender

• USB interface

• 8,192 memory slots, dividable in max. 99 blocks

• Statistic functions

|

|

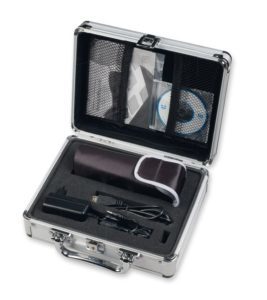

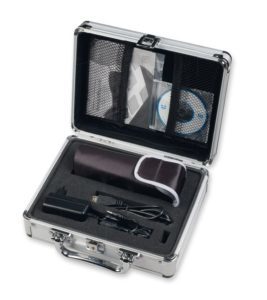

ComBi D3® plus measuring case: ComBi D3® plus measuring case:

• Robust plastic case

• ComBi D3® plus gauge with supporting loop, battery, leather bag, inbuilt zero plates and manual

• Mini-Infrared-Printer SP100

• Statistic functions

• Software on CD with statistic functions

• Spare batteries

• Spare paper roll

• USB cable |

|

| |

|

GlossTector© gauges are small, hand-held instruments for gloss measurement. Lightweight, practical and robust. Available in universal angle and three-angle models: GlossTector® 60° for universal gloss measurement and GlossTector® 20°-60°-85° for measurement in three angles.

GlossTector© 60° is equipped with a universal angle of 60° and determines universal and normal gloss levels.

|

|

|

New! GlossTector 60° plus:

Enables high gloss measurements on metallic surfaces, mirrors and glass. Powerful down to the smallest detail.

• Determination of gloss levels from matt to mirror gloss

• Easy and quick calibration

• Measurement display with good stability characteristics

• High repeat accuracy

• Stable optics with no need for replacement

• Handy design and robust casing for a long service life

• Standard calibration disks from quartz crystal ensure high-precision calibration

• Battery-operated

• Battery warning display

• Calibration based on a single standard

GlossTector© 20°-60°-85° determines the respective levels for high gloss, universal, normal or dull gloss depending on the setting. Easy handling and calibration ensure quick operational readiness for various demands in the production flow and laboratory.

|

|

|

ColorTector Alpha© is a cost-effective colorimeter, equipped with an internal probe and CIE 10° measuring geometry.

Features:

• Stable operation

• Test angle: CIE 10° (standard)

• High accuracy

• Easy to use

• LCD display

• Easy measurement of color contrasts on the same material, e.g. ΔE, ΔL, Δa, Δb, Lab and Lch values

• Power consumption saving

• Alarm signal: continuous sound

• Measurement sound: buzz

|

|

|

TintTector Alpha®

Modern, portable gauge for transmittance measurement.

Tinted car windows are in fashion. However, for safety reasons the transmittance of tinted car windows is regulated by law. The innovative TintTector Alpha© measures the transmittance of tinted car windows and indicates it as a percentage. The gauge is intended for use at technical car inspection centers, during routine police checks for compliance with new regulations and during the production of vehicle windows. To this effect, the gauge complies with the ISO 3538 standard and is suitable for a single person to operate.

Features:

• High repeatability ≤ 0.2 %

• Precise characteristics complying with the spectral response of the human eye during daytime

• Simple calibration procedure

• Certified high-quality optical system

• Optical characteristics comply with ISO 3538

• Easy to use

• Battery-operated

• Complies with EMC

• 3 years warranty

|

|

ComBi D3® plus measuring case:

ComBi D3® plus measuring case:

SaluTron® D1: Combination gauge with interchangeable probes

SaluTron® D1: Combination gauge with interchangeable probes